01 What is bonding wire?

Key alloy wire refers to high-purity gold alloy wire with a purity of 99.99% and a wire diameter of 18-50 μ m. Usually, ball welding wedge welding is used for bonding and is commonly used for plastic resin packaging.

The key alloy wire mainly has the following characteristics: (1) mechanical strength: it is required that the gold wire can withstand the mechanical strength of the stress during resin encapsulation, and has the specified tensile and tensile strength; (2) Good ball forming characteristics; (3) Joinability: The surface of the gold wire is free of scratches, dirt, dust, and other adhesive substances, providing sufficient bonding strength between the gold wire and the semiconductor chip, as well as between the gold wire and the lead frame; (4) Homework: As the length of the gold wire increases, it is necessary to prevent wire jamming and require high precision in the diameter of the gold wire, with no curling on the surface; (6) There are no ripples at the welding point during welding.

Bonding wire is a specialized material for semiconductor packaging and one of the five important structural materials for semiconductor packaging (including bonding wire, lead frame, organic substrate, ceramic packaging, and plastic packaging). The diameter of bonding wire is only a few tens of micrometers to several tens of micrometers. Depending on the material, bonding wire can be divided into bonding alloy wire, bonding copper wire, bonding aluminum wire, alloy gold wire, etc.

Due to its chemical stability, antioxidant properties, and non reactivity with acids and bases, gold made bond alloy wires have good ductility, excellent conductivity, fast gold wire ball bonding speed, and high reliability. They are the earliest and most widely used type of bond wire among various varieties.

Analysis of the preparation process of 02 key alloy wire

The preparation process of bonded gold wire mainly includes four steps: melting casting, drawing, annealing, and winding. The preparation process for such gold wire is basically the same both domestically and internationally.

By using the melting casting process to further purify and control the content of harmful impurities in the raw material gold, and adding trace amounts of alloying elements to improve the mechanical and application properties of the bonding wire, the doping of Pd and Pt can effectively reduce the formation of Au alloy at the interface, Be can enhance the stability of the wire arc, Ca can increase the strength of the wire, and rare earth metals can increase the heat affected zone of the wire, refine particles, and improve thermal stability. 【 1 】

The wire drawing process is to draw the melted gold ingot into fine wires of the target diameter through multiple wire drawing processes such as coarse drawing, medium drawing, and fine drawing. The wire drawing process requires controlling the consistency of the bonding wire diameter, otherwise quality risks such as wire breakage and bonding failure are prone to occur during wire bonding.

After drawing the gold wire into the desired diameter, annealing is required to reduce the increase in hardness caused by the drawing process, resulting in a gold wire with a certain elongation and tensile strength. Generally speaking, the higher the heat treatment temperature, the higher the elongation of the bonded gold wire, while the lower the strength. Finally, the gold wire is wrapped around a spool to form a finished gold wire that can be used on bonding equipment. 【 2 】

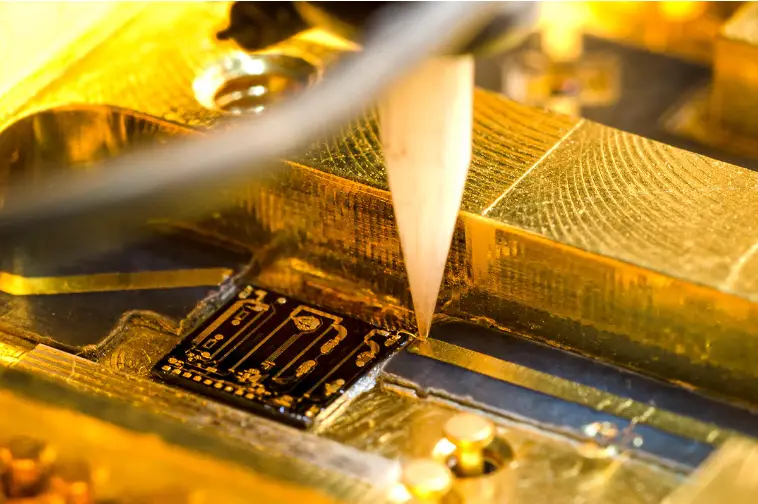

03 Jindingfeng Bond Wire Melting and Casting Furnace

Equipment Introduction: This equipment includes a medium frequency induction heating device, a high vacuum water-cooled casting chamber, a high vacuum device (including an oil rotating system, an oil diffusion pump), a precision traction device, a wire winding device, etc. The interior of the high vacuum water-cooled casting chamber is equipped with induction coils and includes imported high-purity graphite crucibles, casting molds, and crystallizers.

JDF30-GZLX5

References

[1] Chen Yongtai, Wei Kuan, Xie Ming, etc Research progress on precious metal bonding wire materials [J]. Precious Metals, 2014, 35 (3): 66-70. | | | | | | | | | | | | | | | | | [2] Liu Yuanping, Sun Lanlan, Gao Hong, et al Research on the Evaluation System and Application of Key Alloy Wire for Aerospace Applications [J]. Aerospace Materials Technology, 2023, 53 (02): 136-141

Related News