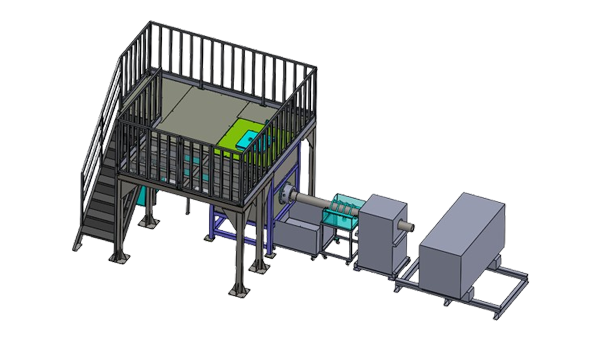

1. Adopting intermediate frequency induction, the melting time is short and the work efficiency is high.

2. By using a high vacuum water-cooled casting chamber, it can prevent the oxidation of metal materials and the mixing of impurities, making it suitable for melting high-purity metal materials or those containing easily oxidizable elements.

3. Adopting mechanical stirring function under high vacuum state, the color is free of segregation.

4. Melting is carried out under high-purity inert gas protection, so the oxidation loss of graphite crucible is minimal.

5. Adopting automatic pouring and pouring, the operation is simpler.

6. The mold adopts automatic heating during the pouring process to better ensure the pouring quality.

7. Equipped with a secondary feeding function, it can effectively control the time of low-temperature metal addition.

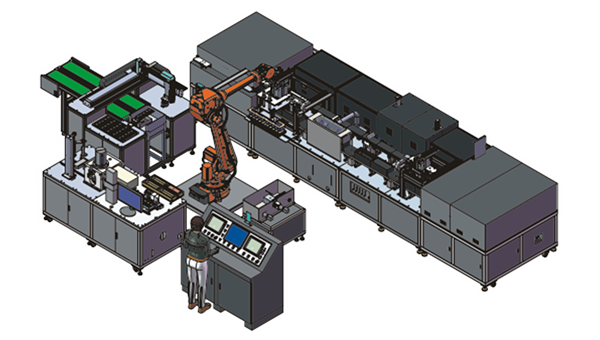

1.Adopt medium frequency induction,short melting time and high work efficiency.

2.The high-vacuum water-cooled casting chamber is used to prevent the oxidation of metal materials and the incorporation of impurities.For this purpose,it is suitable for high-purity metal materials or smelting containing easily oxidized elements.

3.The mechanical stirring function under high vacuum state is adopted,and the color formation is not segregated.

4.The smelting is protected by high-purty inert gas,so the graphite ruthenium has very little oxidation loss.

5.Using automatic pouring and pouring,the operation is simpler.

6.The mold is automatically heated during the pouring process to ensure the quality of the casting.

7.With a secondary feeding function,can effectively control the time of low temperature metal addition.