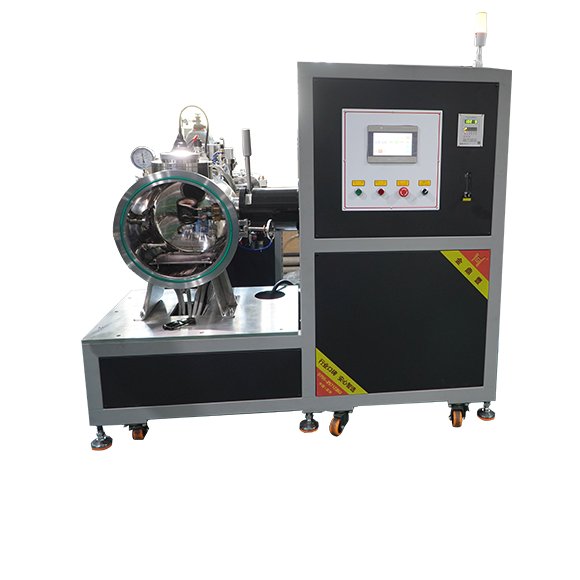

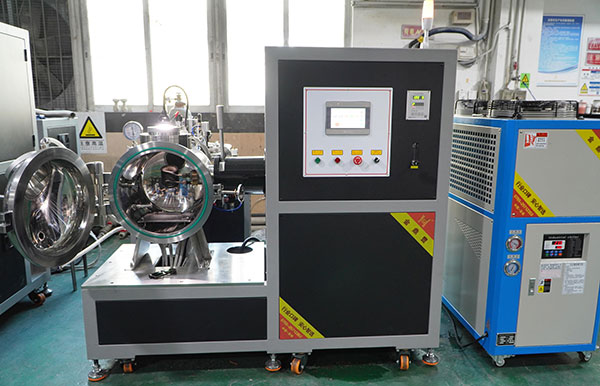

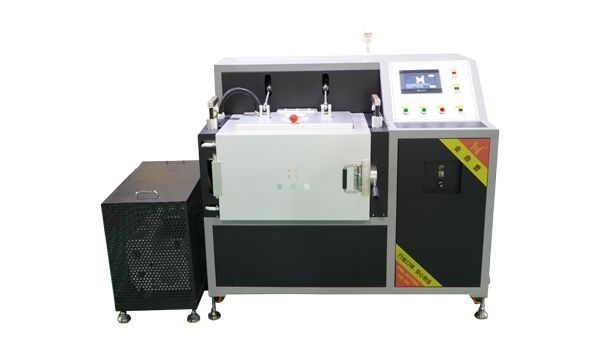

This high vacuum melting furnace can achieve a vacuum degree of 6.7x10 ^ (-3) and a temperature of up to 2100 ° C. It is mainly designed for customers who have high requirements for metal density, and can achieve vacuum melting and vacuum casting with extremely high density.

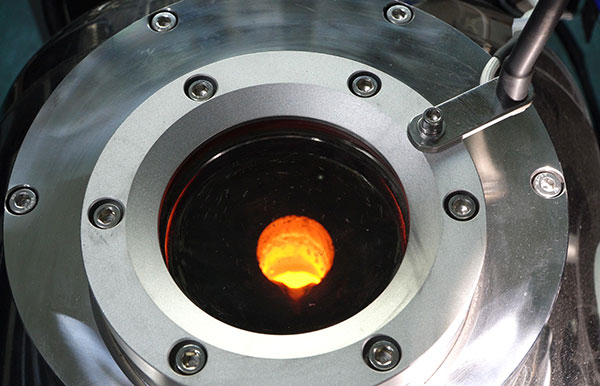

The operation of this device is very simple, with a PLC controlled human-machine interface. It is equipped with a high vacuum composite vacuum gauge that can automatically measure vacuum values. The observation window for pouring allows real-time monitoring of material changes during the melting process. In addition, the machine is equipped with electronic stirring function, making it an essential tool for precious metal refining plants.

This high-vacuum melting furnace can achieve a vacuumlevel of6.7x10^(-3) and a temperature of up to 2100 ° C. lt isprimarily designed for customers with high requirementsfor metal density, enabling vacuum melting and vacuumcasting with extremely high density.

The operation of this equipment is very simple, featuring aPLC-controlled human-machine interface. lt is equippedwith a high-vacuum composite vacuum gauge that canautomatically measure vacuum levels. The observationwindow for pouring allows real-time monitoring of themetal during the melting process.

Additionally, the ma.chine is equipped with an electronic stirring function,making it an essential tool for precious metal refineries.