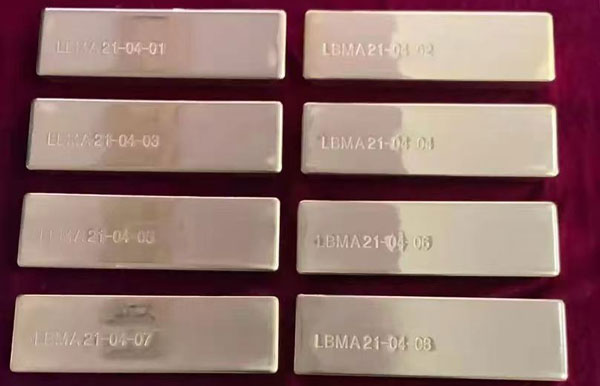

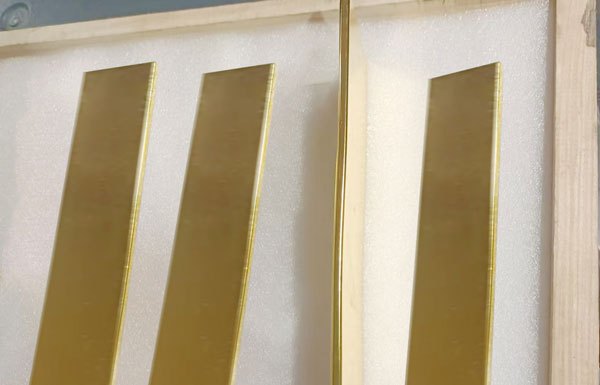

This equipment is independently developed and designed by Jindingfeng. The emergence of this equipment completely replaces the traditional production process of gold and silver bars, completely solving the problems of shrinkage, water waves, oxidation, and unevenness of gold and silver. It uses vacuum melting for rapid prototyping, and the surface of the products produced by this machine is flat, smooth, and has five holes, with almost negligible loss. It adopts automated control to enable general workers to operate multiple machines, greatly saving production costs. It is an essential tool for major precious metal refineries. SY-CH12.5 automatic casting machine, capable of casting 1kg, 3kg, and 12.5kg gold ingots, with a maximum temperature of 1450 ℃, and can melt gold, silver, and copper,; 1kg gold ingots can produce 5 pieces at a time, and 3kg and 12.5kg can produce 1 piece at a time. The melting time is 20-25 minutes per furnace.