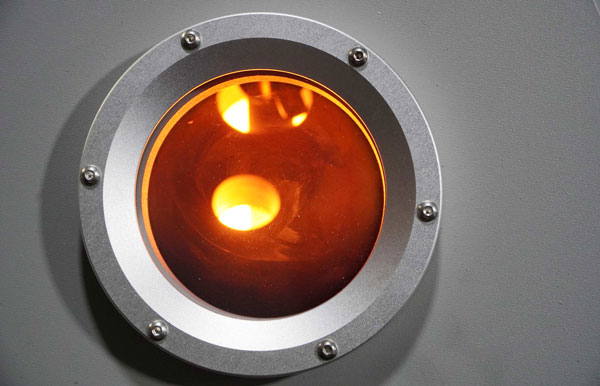

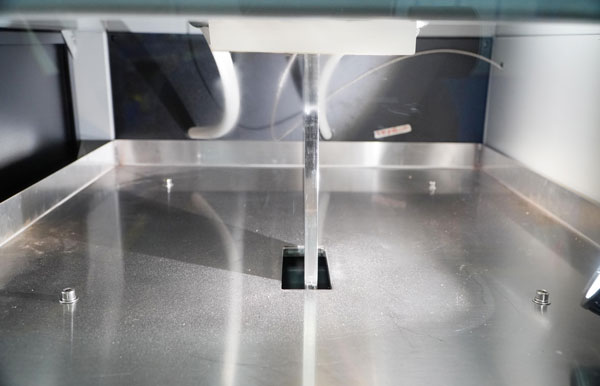

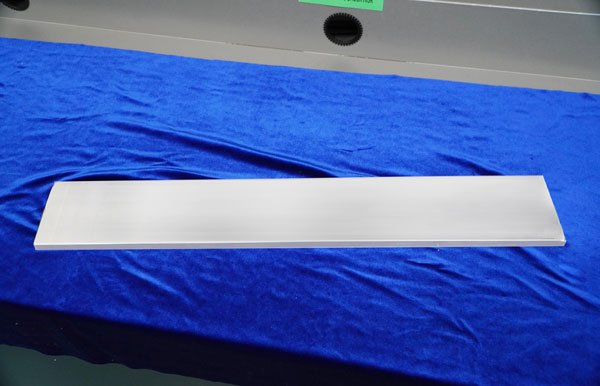

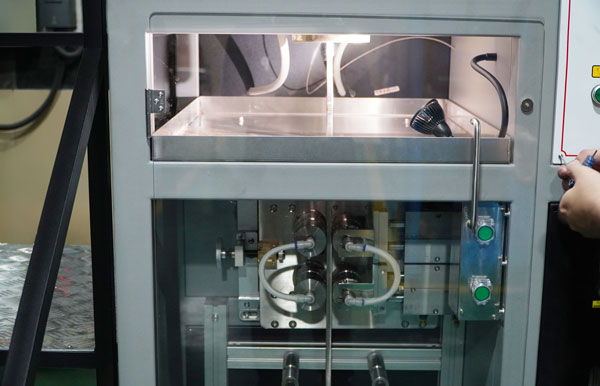

This machine uses inert gas protection to dissolve and prevent metal evaporation, thereby minimizing waste. It can cast high-density alloys such as gold, K-gold, silver, and other irregular profiles, such as circular, square, and hollow tubes. By adopting the next casting method, the sand holes can be controlled to a minimum, and the high efficiency of the electromagnetic stirring function in casting makes the product look more uniform.

This machine using the inert gas to protect thedissolution,preventing the metal vaporization, whichcan reduce thewastages to the minimum range. lt cancast high-densitygold,K gold, silver and otherprecious sheet metals andother irregular profiles likeround, square tube, hollowtube and so on. The sandhole can be controlled to thelowest limited byadopting the next cited method of cast-ing, highefficiency of the electromagnetic stirring functioninthe casting makes the product looks more even.