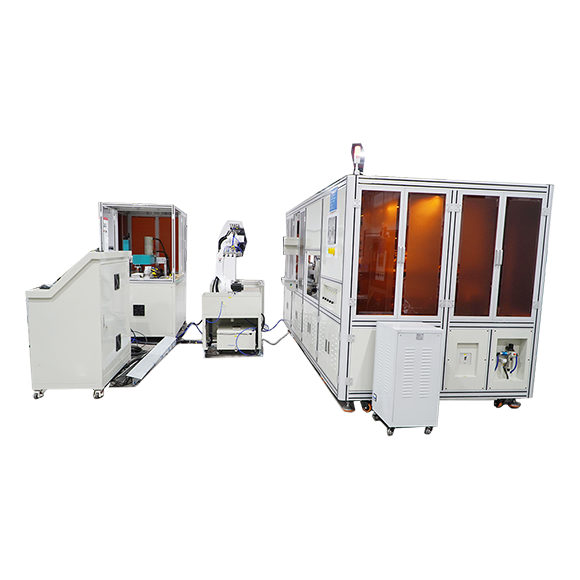

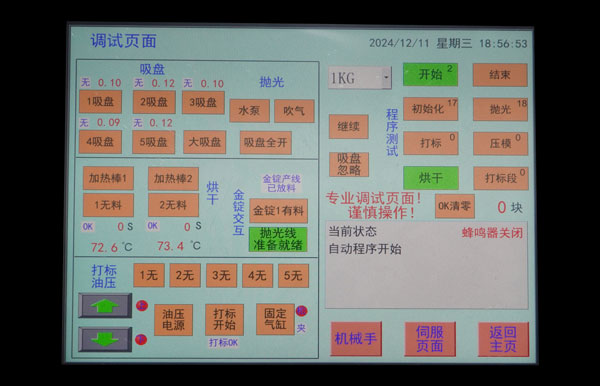

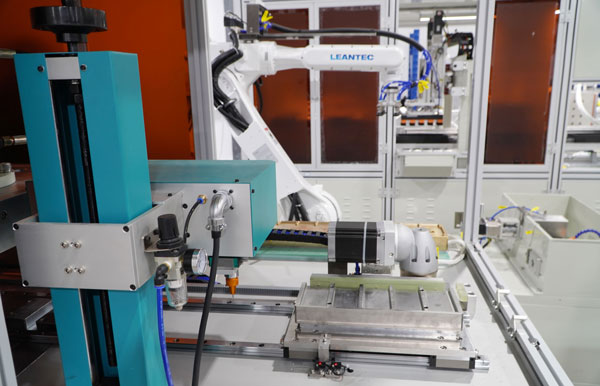

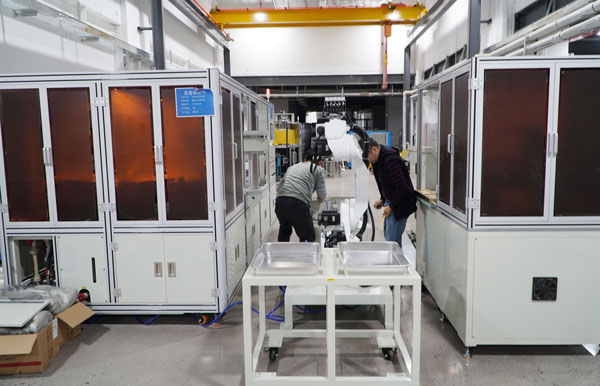

Jindingfeng tunnel type gold ingot equipment can produce 1 kilogram of gold bars, 3 kilograms of gold bars, and 100 grams of gold bars. By using medium frequency induction heating and nitrogen protection, the material is fed into the mold through the feeding system, covered with the mold cover, and fed into the medium frequency furnace, achieving automatic casting, cleaning, coding, palletizing, etc. The finished products produced have a smooth, flat surface, no holes, no shrinkage patterns, no cracks, rounded corners without tooth marks, and meet SGE standards.