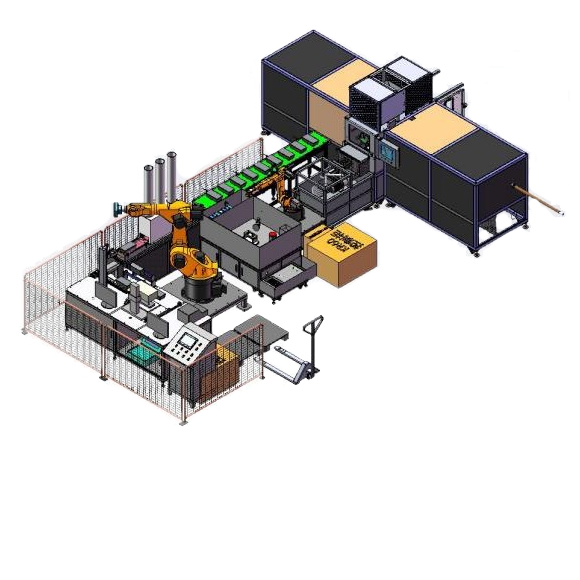

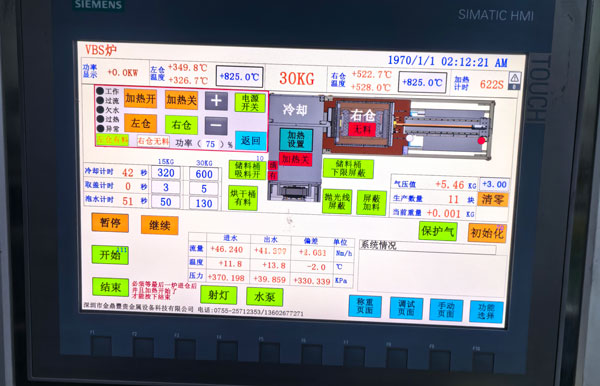

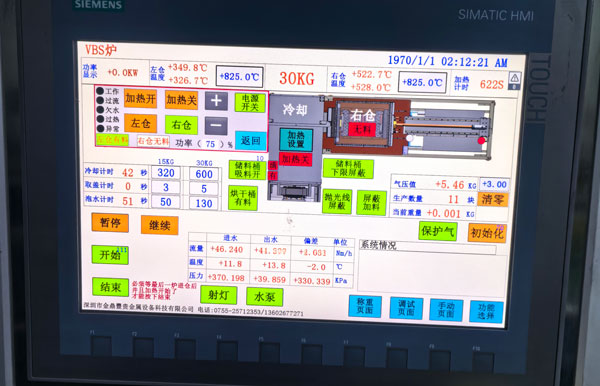

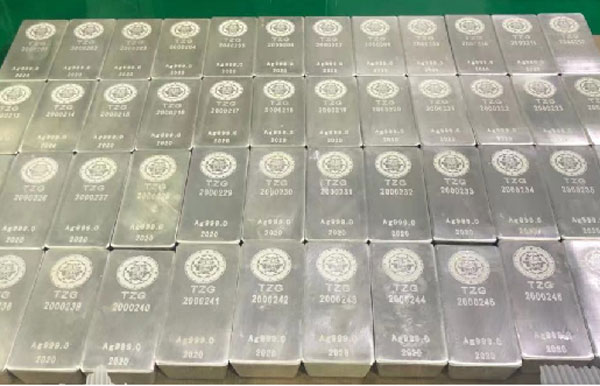

This production line is independently developed and designed by Jindingfeng, with patent number ZL201820013832.0. This equipment replaces the original flameless tunnel melting furnace and is more energy-efficient than tunnel furnaces (with the same efficiency of 350KT for tunnel furnaces and 150KW for VBS furnaces), saving more space. This equipment adopts automatic weighing, automatic melting, automatic ingot melting, automatic demolding, automatic cleaning and polishing, automatic coding, and the entire process does not require manual intervention, truly achieving ingot automation. And it has been realized to be compatible with casting 30KG silver ingots, and can be used by changing the mold. Solved the problems of metal shrinkage, water ripples, oxidation, and unevenness, and quickly melted in one go! The products produced by this production line have a smooth and flawless surface, with almost negligible wear and tear. Adopting fully automated control to improve efficiency is the intelligent modernization choice for enterprise factories.

The production line is independently developed and designed by JinDingfeng,and the patent numberis ZL2018 2 0013832.0. Theequipment replaces the original flameless tunnel melting furnace.which is more energy saving than the tunnel furnace(the sameefficiency tunnel furnace power is 350KW, VBS furnace power is150KW)and saves space.The equipment adopts automaticweighing,automatic melting,automatic melting ingot, automaticstripping,automatic cleaning and polishing, automatic coding thewhole process without manualintervention, truly realized theautomation of ingot casting. lt can be used with casting 30KG silveringots and can be used by replacing the mold, Solve the metalshrinkage,water ripple, oxidation and uneven phenomenon, meltinga rapid prototyping, the product surface produced by the productionline is flat, smooth, no holes, the loss is almost negligible. The use offully automated control, improve efficiency, is the enterprise factoryintelligent modernization choice.